Sharp and Pristine HydroChrome® - Chrome Finishing

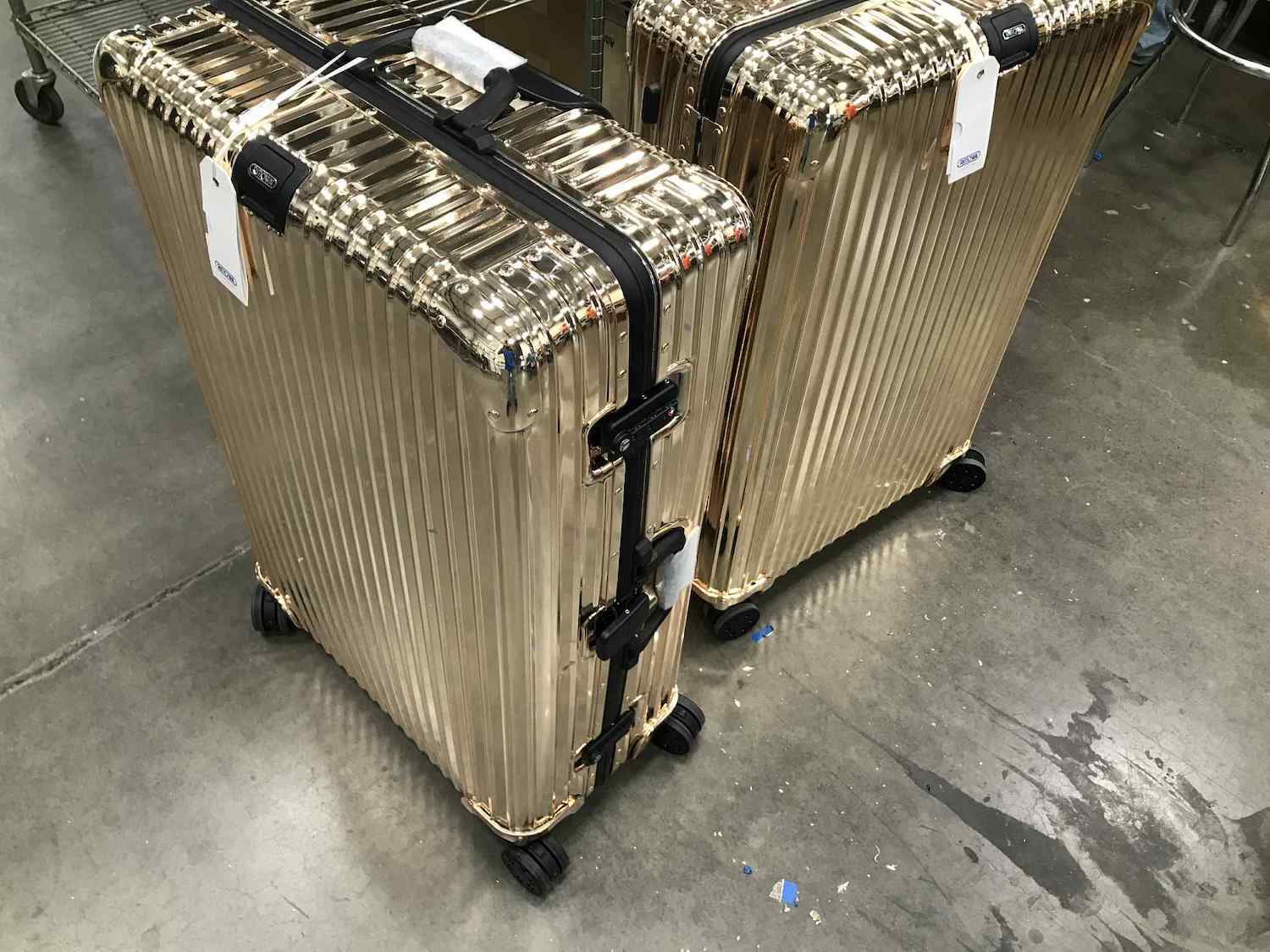

Hydro Graphics Inc. (HGI) utilizes HydroChrome® Chrome-Finishing to create a smooth, metallic, hyper futuristic finish on a range of objects. The chrome finish settles into the details and creases of the project to enhance the visual appeal of the object and create an eye-catching display.

How HydroChrome® Chrome-Finishing is Done at Hydrographics Inc.

HydroChrome® is the use of pure silver plating that is bonded to the object it is applied to. This creates a mirror-like silver finish on surfaces like wood, plastic, fabric, metal, glass, or anything else it is used on. The HydroChrome® finish is durable and can be applied to virtually any surface.

HydroChrome® finishing can be applied to various industries, including automotive, design, art, and industrial sectors. It's versatility and durable properties make it the ideal finish for many projects.

HydroChrome®: The Next Generation of Chrome Finishes

Developed by HGI in 2009, HydroChrome® is a breakthrough coating system that delivers the brilliance of chrome with unmatched versatility. Unlike traditional plating, HydroChrome® can be applied to plastic, wood, aluminum, 3D-printed substrates, and more. HydroChrome® opens up endless possibilities for all sorts of industries. Whether it is used for sporting goods, automotive applications, or consumer products, HydroChrome®is an ideal candidate for the project.

Our hybrid process combines aerospace-grade coatings, hydrographics technology, and a reflective silvering layer. These are then sealed with a durable, impact-resistant clear coat. The result is a mirror-like finish that not only looks stunning but also offers superior durability compared to conventional chrome alternatives.

HydroChrome® comes in a wide spectrum of colors, ranging from bright chrome to gold, red, blue, and black, and is compatible with any hydrographics pattern. HydroChrome® allows for truly unique, custom designs that push beyond the limits of traditional chrome plating.

Chrome Finishing Methods Compared

|

Feature / Process

|

HydroChrome® | Electroplated Chrome | Spray Chrome | Vacuum Metallization |

| Applicable Substrates | Plastic, wood, aluminum, composites, 3D prints, metals | Metals only | Most surfaces (plastic, metal, wood, etc.) | Mainly plastics |

| Durability | High (impact-resistant clear coat, passes helmet testing) | Very high (hardest finish) | Moderate (depends on topcoat) | Low (scratches/tarnishes easily) |

| Reflective Quality | Mirror-like, highly customizable | True chrome, mirror finish | High, but not as deep as plating | Good, but thinner “metallic” look |

| Customization | Wide color spectrum + hydrographics patterns | Limited to chrome look | Some colors with tinted topcoat | Limited, mainly decorative |

| Environmental Impact | No toxic heavy metals | High (hexavalent chromium, hazardous waste) | Lower than plating, still uses chemicals | Lower, but uses vacuum chambers |

| Design Flexibility | Virtually unlimited (shapes, substrates, patterns) | Limited to conductive metals | Flexible, but less durable | Best for lightweight decorative parts |

| Best Uses | Sporting goods, helmets, automotive parts, custom products | Automotive trim, industrial, tools | Signs, decorative items, automotive accessories | Toys, packaging, light decorative parts |